Product Description

BBS Series Stainless Steel Cold Rolled Ball Screw (C5/Ct7/Ct10)

| Table of Shaft dia. and Lead combination for Rolled Ball Screw | ||||||||||||||||

| Lead (mm) | ||||||||||||||||

| 0.5 | 1 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 15 | 20 | 30 | ||

| Shaft dia (mm) | 4 | / | / | |||||||||||||

| 5 | / | |||||||||||||||

| 6 | / | / | / | / | ||||||||||||

| 8 | / | / | / | / | / | / | / | |||||||||

| 10 | / | / | / | / | / | / | / | / | / | |||||||

| 12 | / | / | ||||||||||||||

| 13 | / | / | / | |||||||||||||

| 14 | / | / | ||||||||||||||

| 15 | / | / | / | |||||||||||||

| 16 | ||||||||||||||||

Accuracy Class & Axial Clearance

Accuracy grade of BBS series(standard cold rolled stainless steel ball screw are based on C5,Ct7 and Ct10(JIS B 1192-3).According to accuracy grade, Axial play 0.005(Preload :C5),0.02mm(Ct7) and 0.05mm or less(Ct10).

Material & Surface Hardness

BBS series (standard cold rolled stainless steel ball screws), the screw shaft screw material is SUS440C (induction hardening), the nut material is SUS440 (vacuum hardening), and the surface hardness of the ball screw part is HRC55 or higher.

Shaft End Shape

The shape of the shaft end of the BBS series (standard stainless steel cold-rolled ball screws) has been standardized.

Application:

1. Medical industry

2.Lithium battery industry

3.Solar photovoltaic industry

4. Semi conductor Industry

5. General industry machinery

6. Machine tool

7. Parking system

8. High-speed rail and aviation transportation equipment

9. 3C industry etc

Technical Drawing

Specification List

FACTORY DETAILED PROCESSING PHOTOS

HIGH QUALITY CONTROL SYSTEM

FAQ

1. Why choose CHINAMFG China?

Over the past 14 years, CHINAMFG has always insisted that “products and services” start from Japanese industry standards,taking ZheJiang standards as the bottom line, actively invest in the development of new transmission components and self-experiment and test. With the service tenet of “exceeding customer expectations”, establish a “trusted” partnership.

2. What is your main products ?

We are a leading manufacturer and distributor of linear motion components in China. Especially miniature size of Ball Screws and Linear Actuators and linear motion guideways. Our brand “KGG” stands for ” Know-how,” ” Great Quality,” and ” Good value” and our factory is located in the most advanced city in China: ZheJiang with the best equipment and sophisticated technology, completely strict quality control system. Our aim is to supply world leader class linear motion components but with most reasonable price in the world.

3. How to Custom-made (OEM/ODM)?

If you have a product drawing or a sample, please send to us, and we can custom-made the as your required. We will also provide our professional advices of the products to make the design to be more realized & maximize the performance.

4. When can I get the quotation?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price,please call us or tell us in your email so that we will regard your inquiry priority.

5. How can I get a sample to check the quality?

After confirmation of our quoted price, you can place the sample order. The sample will be started after you CHINAMFG back our detailed technical file.

6. What’s your payment terms?

Our payment terms is 30% deposit,balance 70% before shipment. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Precision: | C7 |

|---|---|

| Screw Diameter: | 4mm |

| Flange: | With Flange |

| Nut Number: | Single |

| Rows Number: | 4-Row |

| Nut Type: | Circulator |

| Customization: |

Available

|

|

|---|

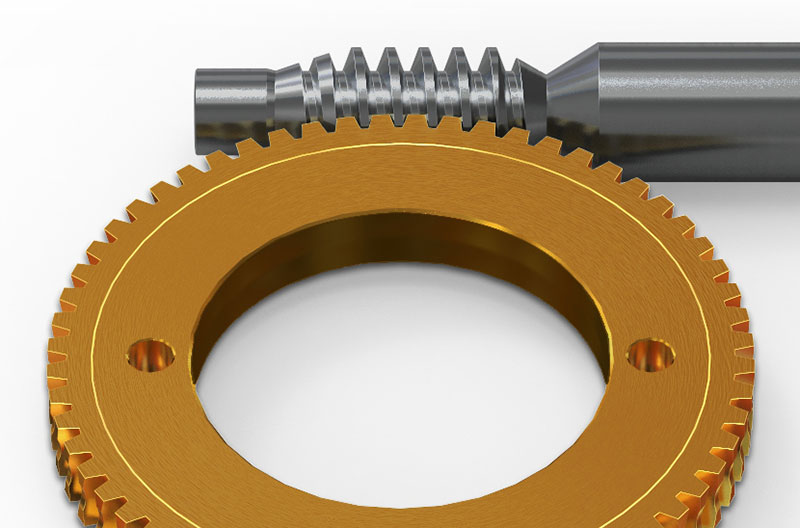

What are the common issues or failures associated with worm screws?

Worm screws, like any mechanical component, can experience certain issues or failures over time. Understanding these common problems is important for proper maintenance and troubleshooting. Here are some common issues or failures associated with worm screws:

- Wear and Surface Damage: Due to the sliding contact between the threads of the worm screw and the teeth of the worm wheel, wear can occur over time. This wear can lead to surface damage, such as pitting, scoring, or galling. Excessive wear and surface damage can affect the performance and efficiency of the worm screw gear system, resulting in increased backlash, decreased torque transmission, and potential failure.

- Lubrication Problems: Inadequate or improper lubrication is a common cause of issues in worm screw systems. Insufficient lubrication can lead to increased friction, heat generation, and accelerated wear. On the other hand, over-lubrication can cause excessive drag and fluid churn, leading to inefficient power transmission. It is important to follow the manufacturer’s recommendations for lubrication intervals, types of lubricants, and proper lubrication techniques to ensure optimal performance and longevity of the worm screw system.

- Backlash and Inaccuracy: Backlash refers to the play or clearance between the threads of the worm screw and the teeth of the worm wheel. Excessive backlash can result in reduced accuracy, loss of motion control, and diminished overall system performance. Backlash can be caused by factors such as wear, misalignment, or improper assembly. Regular inspection and adjustment of backlash are necessary to maintain the desired precision and minimize the effects of backlash-related issues.

- Misalignment: Misalignment between the worm screw and the worm wheel can result in increased friction, wear, and inefficiencies. Misalignment can occur due to factors such as improper installation, component deformation, or external forces. It is essential to ensure proper alignment during installation and periodically check for misalignment during routine maintenance. Adjustments should be made as necessary to maintain optimal performance and prevent premature failure.

- Overloading: Subjecting the worm screw gear system to excessive loads beyond its design limits can lead to failure. Overloading can result in accelerated wear, tooth breakage, or component deformation. It is important to operate the system within the specified load limits and consider factors such as shock loads, dynamic loads, and variations in operating conditions. If higher loads are required, it may be necessary to select a worm screw system with a higher load capacity or redesign the system accordingly.

- Corrosion and Contamination: Corrosion and contamination can negatively impact the performance and lifespan of worm screw systems. Exposure to moisture, chemicals, or abrasive particles can lead to corrosion, rusting, or damage to the surfaces of the worm screw and worm wheel. Contamination can interfere with smooth operation and cause accelerated wear. Proper environmental protection, regular cleaning, and appropriate sealing measures can help mitigate the effects of corrosion and contamination.

- Insufficient Stiffness: Worm screws rely on proper support and stiffness to maintain accurate positioning and prevent deflection. Inadequate stiffness in the supporting structure or mounting arrangement can result in excessive deflection, misalignment, and decreased performance. It is crucial to ensure that the worm screw system is properly supported and mounted to maintain the required rigidity and stiffness for optimal operation.

It’s important to note that the specific issues or failures associated with worm screws can vary depending on factors such as the application, operating conditions, maintenance practices, and the quality of the components. Regular inspection, proper lubrication, alignment checks, load monitoring, and adherence to manufacturer guidelines are essential for minimizing the occurrence of these issues and ensuring the reliable and efficient operation of worm screw systems.

How do environmental factors affect the lifespan and performance of worm screws?

Environmental factors can have a significant impact on the lifespan and performance of worm screws. Here are some ways in which different environmental conditions can affect worm screw operation:

- Temperature: Extreme temperatures can affect the material properties of worm screws. High temperatures can cause thermal expansion, leading to increased clearances and reduced efficiency. It can also accelerate wear and degradation of lubricants, leading to increased friction and potential damage. Conversely, extremely low temperatures can make lubricants less effective and increase the risk of brittle fracture or reduced flexibility in materials.

- Humidity and Moisture: Exposure to high humidity or moisture can lead to corrosion and rusting of worm screws, especially when they are made of materials that are not resistant to moisture. Corrosion can cause surface pitting, reduced strength, and accelerated wear, ultimately compromising the performance and lifespan of the worm screw.

- Dust and Contaminants: Dust, dirt, and other contaminants present in the environment can enter the worm gear system and cause abrasive wear on the worm screw. These particles can act as abrasives, accelerating the wear of the contacting surfaces and potentially leading to premature failure or reduced performance. Regular cleaning and maintenance are essential to mitigate the effects of dust and contaminants.

- Chemical Exposure: Exposure to chemicals, such as acids, solvents, or corrosive substances, can have a detrimental effect on worm screws. Chemicals can corrode the surfaces, degrade lubricants, and affect the material properties, leading to reduced lifespan and compromised performance. Choosing materials and coatings that are resistant to specific chemicals present in the environment is crucial for long-term performance.

- Load and Overloading: Environmental conditions, such as heavy loads or overloading, can significantly impact the lifespan and performance of worm screws. Excessive loads can lead to increased stress levels, deformation, and accelerated wear on the worm screw. It is important to operate worm gear systems within their specified load capacities and avoid overloading to ensure optimal performance and longevity.

- Operating Speed: The operating speed of the worm screw can also be influenced by environmental factors. High-speed applications may generate more heat due to friction, necessitating effective cooling mechanisms. On the other hand, low-speed applications may exhibit reduced lubrication effectiveness, requiring specific lubricants or maintenance practices to ensure proper lubrication and prevent excessive wear.

To mitigate the effects of environmental factors, proper maintenance, regular inspection, and suitable protective measures are essential. This includes using appropriate lubricants, implementing effective sealing mechanisms, applying protective coatings, and considering environmental factors during the design and material selection process. By considering and addressing environmental factors, the lifespan and performance of worm screws can be optimized, ensuring reliable operation in various operating conditions.

What are the typical applications of worm screws in machinery?

Worm screws, also known as worm gears or worm gear screws, have a wide range of applications in machinery where motion transmission and torque multiplication are required. Their unique characteristics make them suitable for various industries and applications. Here are some typical applications of worm screws in machinery:

- Conveyor Systems: Worm screws are commonly used in conveyor systems to control the movement of materials. They provide precise speed reduction and torque multiplication, allowing for efficient transportation of goods in industries such as manufacturing, packaging, and logistics.

- Lifting Mechanisms: Worm screws are extensively used in lifting mechanisms, such as screw jacks or worm gear lifts. They provide reliable and controlled vertical motion for lifting heavy loads in applications like automotive service garages, construction sites, and material handling equipment.

- Winches and Hoists: Worm screws are employed in winches and hoists to provide high torque and controlled lifting or pulling operations. They are commonly used in applications such as cranes, marine equipment, elevators, and stage rigging.

- Rotary Actuators: Worm screws are utilized in rotary actuators to convert the input rotary motion into a controlled rotary output motion. This makes them suitable for applications like valve actuators, positioning systems, and robotic joints.

- Automotive Applications: Worm screws find use in automotive applications, particularly in steering systems. They are employed in steering gearboxes to convert the rotary motion from the steering wheel into the lateral motion required for steering the vehicle.

- Machine Tools: Worm screws are used in machine tools, such as milling machines, lathes, and drill presses, to control various linear and rotary movements. They provide precise positioning and motion control for cutting, shaping, and drilling operations.

- Printing and Packaging Machinery: Worm screws are employed in printing and packaging machinery to control the movement of printing heads, cutting blades, and packaging components. They ensure accurate and synchronized motion for high-quality printing and packaging processes.

- Robotics: Worm screws are utilized in robotics for precise and controlled motion in robotic arms, grippers, and other robotic mechanisms. They enable accurate positioning and smooth motion control in industrial automation and robotic applications.

These are just a few examples of the typical applications of worm screws in machinery. Their ability to provide high gear reduction ratios, precise motion control, and self-locking characteristics make them suitable for a wide range of industries, including manufacturing, construction, automotive, robotics, and many others where efficient power transmission and controlled motion are essential.

editor by CX 2024-03-28