Real Estate

WORM SCREW

AND

WORM GEARS

A worm gear system consists of a worm (pinion) and a worm gear (worm gear) positioned as intersecting shafts, and is typically used where high gear ratios are required and space is limited.

Worm gear drives help reduce speed and allow for higher torque to be delivered. Gearboxes that use worm gears will be more compact than those built using most other gearing options.

With these features, common worm gear applications include presses, small engines, lifts and elevators, rolling mills, conveying engineering, mining industry machines and worm drive saws. Advantages of worm gears are low noise and low vibration. CZPT Gear can design and make worm gear systems in hardened steel, bronze or nonmetallic options. As long as they are properly mounted and lubricated, worm gears are known to run smoothly and quietly.

WORM SCREW

WORM GEAR CAPABILITIES

- Pitch diameter range: ½” to 49”

- Diametric pitch range: 3 to 24

Worm gears can easily be an effective and reliable piece of equipment. For custom worms and worm gears made to your exact specifications, contact us or request a quote today.

Services

Customize, Sell, List, Display, Check, Your Brand!

CUSTOM IS OUR SPECIALTY

Our experienced team of Customer Service Representatives, Application Engineers, Design Engineers, and Manufacturing Engineers are ready to take on the challenge. Let us apply our expertise to develop a custom solution to suit your needs. We can design and manufacture any type of worm drive gearbox application you need.

PRODUCT VARIETY

The CZPT worm screw covers a wide range of markets. We offer a variety of output options to accommodate the largest diameter and small worm gears required. If you are looking for a solution for your worm application, CZPT has the answer and a range of products to support it.

CONE DRIVE QUALITY

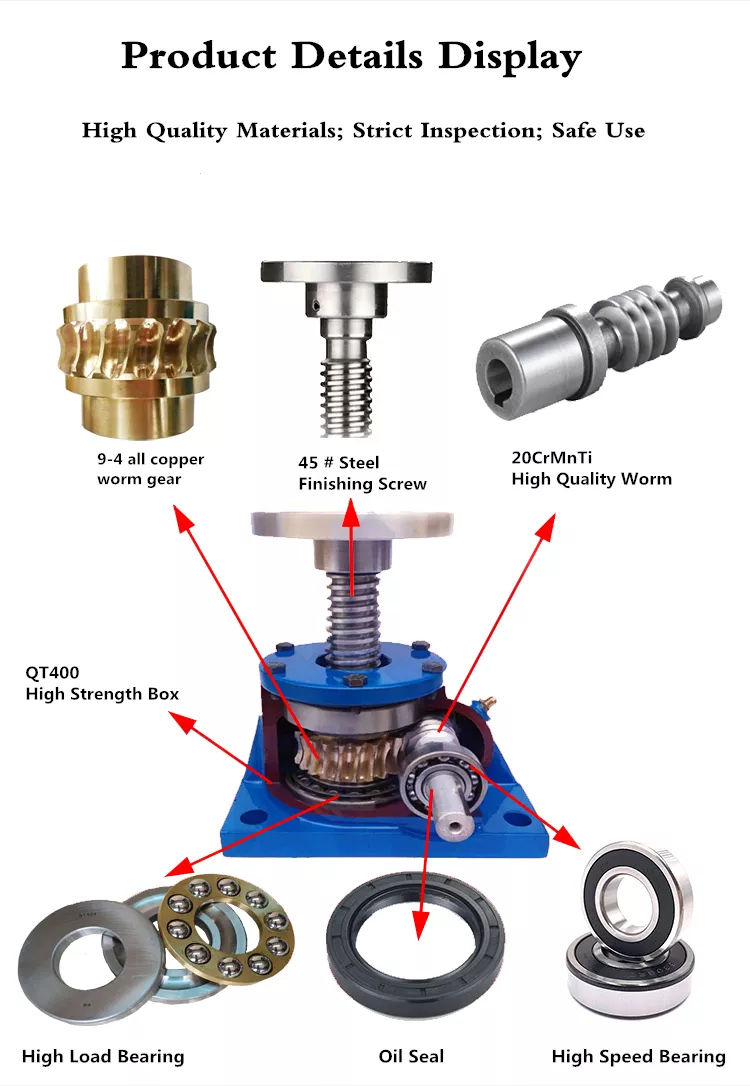

- Quality Engineering: We will design the right worm screw for your application and build it with the finest materials and components.

- Quality Manufacturing: We operate with a strict attention to detail and manufacture to exact tolerances and dimensions. Your worm screw will be built with precision and accuracy.

- Quality Service: When you need assistance with installation, CZPT Drive will be there to support you. We are fully committed to offering you service before and after the sale.

OUR TEAM

CZPT Drive has a team of highly qualified, high character individuals to help if you have questions at any time throughout the purchasing process. Give us a call and we will offer dedicated, personal support to help get you started and identify what product will best fit your application.

Shop

Featured Products for Sale

Crane Parts Brass Worm Double Envelope Worm and Worm Gear

SWL100 worm screw lift trapezoidal screw jack lift QTA/SWL

Worm gear lifting table liftingweight screw elevator

Worm gear worm elevator lead screw jack hand screw reducer

Automatic door system

lifter

Speed reducers

Agriculture

Worm Gear Screw Jacks – Compact and Simple

The CZPT-Gear worm gear screw jack is designed to be compact and straightforward, and its modular construction allows great flexibility in choosing gears, mounting options, flanges, oil types, and surface treatments. If a custom gearbox is required, it must be optimized for specific requirements, and a modular design is also ideal. That’s why we can manufacture a worm gear screw jack that meets your needs at an attractive price.

Worm gears at work

Worm gears are required whenever two shafts cross at an angle less than 90°. They are used to transmit rotational motion from the shaft to the worm gear. It is important that the gears of the two parts interlock without slipping. The worm gear is quiet and capable of high torque. Helical gears and worm gears are mainly used for:

- Presses as power gears

- Roller drives

- Steering systems in conveyor technology

- Mining machinery

- As duplex worm gears in milling heads and rotary tables.

Why Use Worm Gears?

Worm gears are helpful in many different systems. They are often used in presses, rudders, and conveyor belts because of their ability to brake quickly and withstand a lot of shocks. This also makes them ideal for use in elevators/lifts, as they can carry a lot of weight and are fairly easy to stop. Worm gears are also ideal for reducing system noise or where space is limited – making them common in some small electric motors and in instruments like guitars and banjos.

From My Blog

China Custom High Speed Worm Lathe Machine for Worm Gear

Product Description View More How do you select the right worm screw for a specific application? Selecting the right worm screw for a specific application involves considering several factors to ensure optimal performance and compatibility. Here are the key steps to...

China factory CNC Thread Turning Milling Lathe Machine for Motor Shaft Worm Gear

Product Description View More Can worm screws be used for high torque applications? Yes, worm screws can be used for high torque applications. The design of a worm screw mechanism allows for efficient torque transmission and multiplication, making it suitable for...

China manufacturer Roller Trapezoidal Thread Open Screw Lead Screw Tr36X6

China best Non-Standard Multi-Start Trapezoidal Thread Lead Screw

China Professional Set Trapezoidal Thread Rod CHINAMFG Lead Screw with POM Screw Nuts

China best CHINAMFG 7/8-4 Trapezoidal Drive Thin Thread Tooth Lead Screw with Nut

We offer our Worm Gear Screw Jacks

Four versions:

- Rotary trapezoidal spindle

- Stalled Trapezoid Spindle and Swivel Nut

- Rotary Ball Screw Spindle

- Dead Ball Spindle and Swivel Nut