Product Description

LXK350B CNC screw milling machine is a series of screw processing machine tools developed by our company leading varieties, the product is designed for the processing of equal lead, variable lead, gradual lead, equal groove depth, variable groove depth and other special-purpose screw machine.

| project | details | units |

| Bed width | 800 | mm |

| The length of the lathe bed | 6700 | mm |

| Bed guide rail | Mountain track + horizontal track | |

| Maximum workpiece length | 5000 | mm |

| Maximum machining length | 4700 | mm |

| Maximum milling diameter | Φ 350 | mm |

| Center height of machine tool | 500 | mm |

| Chuck specifications | K11-400 | |

| Milling head motor power | 11 (frequency) | Kw |

| Mill head transmission ratio | 3 1:3. | |

| Milling cutter speed rating | 400 | r/min |

| Spindle mounting taper of milling head | “(69.85) Φ | |

| Milling head down adjustment range | – 5 to + 10 | mm |

| Milling head adjustable Angle | Plus or minus 30 | The degree of |

| C-axis servo motor torque | 22 | N.m |

| C shaft speed | 0 to 5 | r/min |

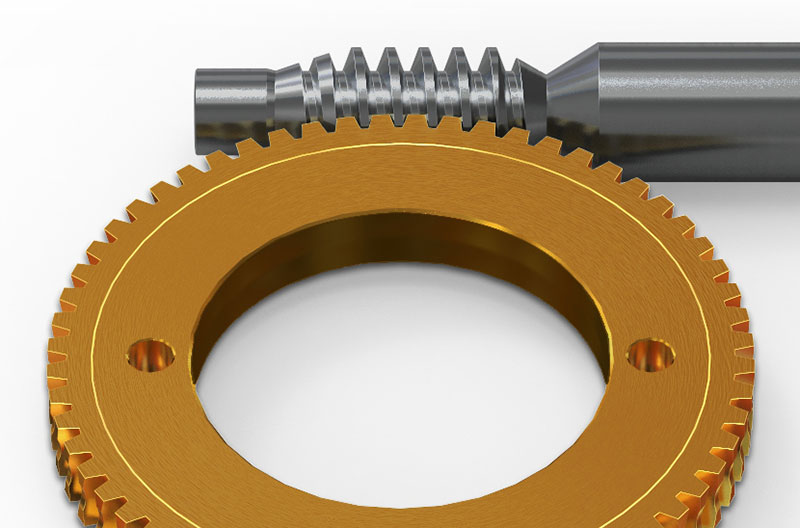

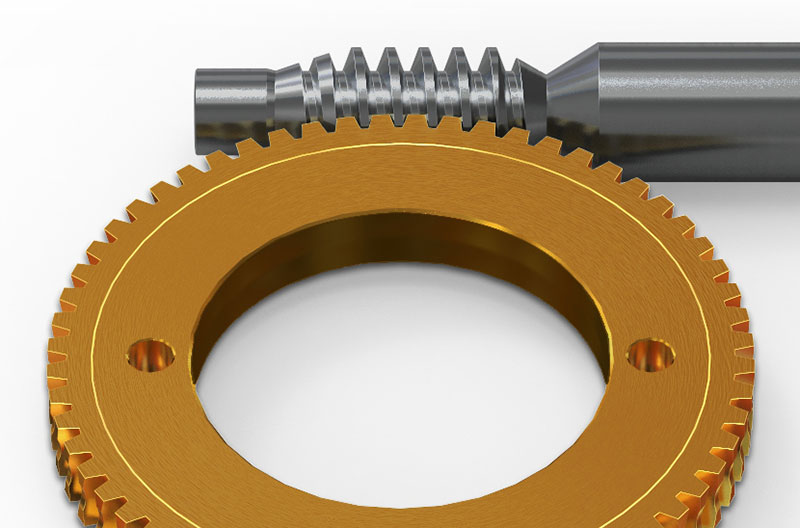

| C axis drive form | Worm gear and worm | |

| C axis transmission ratio | 1:30 0 | |

| C axis positioning accuracy | 10 | Angle of seconds |

| X axis servo motor torque | 15 | N.m |

| X axis drive form | Ball screw + synchronous wheel | |

| X axis guide rail pair type | 55 ° dovetail | |

| X axis ball screw specifications | 4005 | |

| X axis positioning accuracy | 0.02 | mm |

Q1, How do I send my query?

You can contact us via email, phone, instant messaging (WhatsApp, , Skype).

Q2,If you don’t know which model is suitable for your company, please tell us your requirements for the equipment, or you can send us the product drawings, and our engineers can help you choose the most suitable model for you.

Q3,delivery time

The project will be completed within 20 days after receiving the deposit. Please communicate with the sales staff about the specific construction period.

Q4,Payment Terms

30% by T/T as down payment, balance 70% by T/T before delivery. If others payment terms, we can discuss.Welcome to inquiry sales.

Q5,Can your engineers come to help us install and debug the machine?

Yes, our engineers are available to travel to your place. Round flight tickets & accommodation will be at your cost.

Q6, If I can’t know how to operate. Can your engineer help me programme well on machine?

Sure. You can provide your detailed sample drawing.engineer can programme well on machine. Or in some machines, we will put into U-disc of operation video to help you.

Q7,Is there only 1 model of this device?

The standard processing diameter range of this equipment is 350mm, if you have other processing range, you can negotiate with the sales contact. Length range, we can do from 1000mm to 8000mm, and all are integral cast bed.

Q8, processing efficiency

Our CNC machine tool from the lathe bed casting weight, wide guide rail, large motor power, can use a maximum diameter of 50 round rod milling cutter processing, the maximum cutting depth can reach 40mm, so the processing efficiency is very high.

Q9,What control system does the equipment use

Our standard configuration is HangZhou CNC system, fanuc and CHINAMFG can also be used, but the price is slightly different, please contact sales for details.

Remark : Our company produces all kinds of milling and grinding machines , please send me your machining diameter range, drawings or pictures of workpieces , and I will provide more detailed machinery parameters .

| After-sales Service: | Available |

|---|---|

| Warranty: | 3 Years |

| Transport Package: | Seaworthy Wooden Cases |

| Specification: | 5000*2100*2100 |

| Trademark: | Kangnuo |

| Origin: | Cangzhou, Hebei, China |

| Customization: |

Available

|

|

|---|

Can worm screws be used for high torque applications?

Yes, worm screws can be used for high torque applications. The design of a worm screw mechanism allows for efficient torque transmission and multiplication, making it suitable for applications that require high torque output. Here are some key points to consider regarding the use of worm screws in high torque applications:

- Gear Reduction: One of the primary advantages of a worm screw mechanism is its ability to provide a significant gear reduction in a single stage. The helical threads of the worm screw and the meshing teeth of the worm wheel create a high reduction ratio, which results in a lower output speed and higher output torque. This gear reduction capability allows worm screws to generate and transmit substantial torque, making them well-suited for high torque applications.

- Efficiency: While worm screws can provide high torque output, it’s important to consider the mechanical efficiency of the system. The efficiency of a worm screw mechanism can vary depending on factors such as the materials used, lubrication, and design parameters. However, compared to other gear systems, worm screw mechanisms tend to have lower efficiency due to inherent friction between the threads and teeth. It’s crucial to ensure that the efficiency of the worm screw mechanism meets the requirements of the specific high torque application.

- Load Holding: Another advantage of worm screws is their self-locking property. Due to the helical shape of the threads, the worm screw has a wedging effect on the worm wheel, which provides resistance against backward rotation. This self-locking feature allows worm screws to hold loads in a fixed position without the need for additional braking mechanisms. In high torque applications where load holding is required, worm screws can provide reliable and secure positioning.

- Material Selection: The materials used for the worm screw and worm wheel should be carefully selected to withstand high torque loads. Both components should have sufficient strength and wear resistance to handle the transmitted torque without deformation or premature failure. Depending on the specific application requirements, materials such as hardened steel, bronze, or other alloys may be chosen to ensure the durability and performance of the worm screw assembly.

- Lubrication and Maintenance: Proper lubrication is crucial for the smooth operation and longevity of a worm screw mechanism, especially in high torque applications. Adequate lubrication helps reduce friction, wear, and heat generation between the contacting surfaces, ensuring efficient torque transfer. Regular maintenance, including monitoring lubricant levels and replenishing or replacing the lubricant as needed, is essential to maintain optimal performance and prevent premature wear or failure.

Overall, worm screws can be effectively used in high torque applications, thanks to their gear reduction capabilities, load-holding properties, and efficient torque transmission. However, it’s important to carefully consider factors such as mechanical efficiency, material selection, lubrication, and maintenance to ensure that the worm screw mechanism can meet the specific requirements and demands of the high torque application.

Are there different types of worm screws available?

Yes, there are different types of worm screws available to suit various applications and requirements. The design and characteristics of a worm screw can vary based on factors such as the material used, the thread geometry, the type of worm wheel, and the intended application. Here are some common types of worm screws:

- Standard Worm Screws: Standard worm screws are the most commonly used type and are available in a wide range of sizes and materials. They typically have a single-start thread and are made from materials such as steel, stainless steel, or bronze. Standard worm screws are suitable for general-purpose applications where moderate precision and load capacity are required.

- Double-Enveloping Worm Screws: Double-enveloping worm screws, also known as hourglass worm screws, have a unique thread profile that improves contact and load distribution between the worm screw and the worm wheel. This design offers enhanced torque transmission, higher efficiency, and increased load-carrying capacity compared to standard worm screws. Double-enveloping worm screws are often used in heavy-duty applications, such as gearboxes and high-load power transmission systems.

- Low-Lead Worm Screws: Low-lead worm screws have a smaller thread lead angle compared to standard worm screws. This design reduces the amount of sliding contact between the threads of the worm screw and the teeth of the worm wheel, resulting in lower friction and improved efficiency. Low-lead worm screws are commonly used in applications where high efficiency and reduced heat generation are critical, such as in precision machinery and high-speed gear systems.

- Self-Locking Worm Screws: Self-locking worm screws are designed to have a high friction angle between the threads, making them capable of preventing reverse motion or backdriving. This self-locking feature eliminates the need for additional braking mechanisms or external locking devices in certain applications. Self-locking worm screws are commonly used in vertical lift systems, hoists, and other applications where holding the load position is essential.

- High-Precision Worm Screws: High-precision worm screws are manufactured to tighter tolerances and have improved accuracy compared to standard worm screws. They are designed to provide precise positioning and motion control in applications where high accuracy and repeatability are required. High-precision worm screws are often used in CNC machines, robotics, and other precision equipment.

- Customized Worm Screws: In addition to the standard types mentioned above, worm screws can also be customized to meet specific application requirements. Customized worm screws may involve variations in thread geometry, pitch, diameter, materials, or other parameters to suit unique applications or performance specifications.

The selection of the appropriate type of worm screw depends on factors such as the desired load capacity, efficiency requirements, backlash tolerance, positional accuracy, and environmental conditions. It is important to consult with manufacturers, engineers, or experts familiar with worm screw applications to determine the most suitable type for a specific application.

What are the typical applications of worm screws in machinery?

Worm screws, also known as worm gears or worm gear screws, have a wide range of applications in machinery where motion transmission and torque multiplication are required. Their unique characteristics make them suitable for various industries and applications. Here are some typical applications of worm screws in machinery:

- Conveyor Systems: Worm screws are commonly used in conveyor systems to control the movement of materials. They provide precise speed reduction and torque multiplication, allowing for efficient transportation of goods in industries such as manufacturing, packaging, and logistics.

- Lifting Mechanisms: Worm screws are extensively used in lifting mechanisms, such as screw jacks or worm gear lifts. They provide reliable and controlled vertical motion for lifting heavy loads in applications like automotive service garages, construction sites, and material handling equipment.

- Winches and Hoists: Worm screws are employed in winches and hoists to provide high torque and controlled lifting or pulling operations. They are commonly used in applications such as cranes, marine equipment, elevators, and stage rigging.

- Rotary Actuators: Worm screws are utilized in rotary actuators to convert the input rotary motion into a controlled rotary output motion. This makes them suitable for applications like valve actuators, positioning systems, and robotic joints.

- Automotive Applications: Worm screws find use in automotive applications, particularly in steering systems. They are employed in steering gearboxes to convert the rotary motion from the steering wheel into the lateral motion required for steering the vehicle.

- Machine Tools: Worm screws are used in machine tools, such as milling machines, lathes, and drill presses, to control various linear and rotary movements. They provide precise positioning and motion control for cutting, shaping, and drilling operations.

- Printing and Packaging Machinery: Worm screws are employed in printing and packaging machinery to control the movement of printing heads, cutting blades, and packaging components. They ensure accurate and synchronized motion for high-quality printing and packaging processes.

- Robotics: Worm screws are utilized in robotics for precise and controlled motion in robotic arms, grippers, and other robotic mechanisms. They enable accurate positioning and smooth motion control in industrial automation and robotic applications.

These are just a few examples of the typical applications of worm screws in machinery. Their ability to provide high gear reduction ratios, precise motion control, and self-locking characteristics make them suitable for a wide range of industries, including manufacturing, construction, automotive, robotics, and many others where efficient power transmission and controlled motion are essential.

editor by CX 2023-11-27