Product Description

| Table1 | |||||

| No. | Component | Material | |||

| 1 | Screw rod | JIS G 4051-S 25C | |||

| 2 | Fork | ||||

| 3 | Dead eye | JIS G 5501-FC15 | |||

| 4 | Joining HangZhou and hexagon nut | JIS G 4051-S 25C | |||

| 5 | Check plate | Steel plate | |||

| 6 | Fixing bolt | Steel bar | |||

| 7 | Washer | Steel plate | |||

| (mm) | |||||

| Size | Wire Rope | Use Length | W.L.L. | Self- | |

| Diameter | Max | Min | (kN) | Weight(kg) | |

| 14 | 14 | 700 | 488 | 20.6 | 6.0 |

| 16 | 16 | 770 | 538 | 25.5 | 8.6 |

| 18 | 18 | 836 | 590 | 32.4 | 11.6 |

| 22 | 20 or 22.4 | 908 | 638 | 50.0 | 14.8 |

| 24 | 24 | 968 | 688 | 57.9 | 19.4 |

| 25 | 25 | 1004 | 720 | 67.7 | 23.9 |

| 30 | 28 or 30 | 1074 | 770 | 90.2 | 30.3 |

| 32 | 32 | 1124 | 810 | 103.0 | 36.3 |

| 34 | 34 | 1176 | 850 | 112.8 | 43.3 |

| 36 | 36 | 1238 | 900 | 127.5 | 51.3 |

| 38 | 38 | 1284 | 938 | 142.2 | 60.1 |

| 40 | 40 | 1344 | 988 | 161.8 | 70.9 |

| 42 | 42.5 | 1444 | 1068 | 181.4 | 93.8 |

| 45 | 45 | 1482 | 1100 | 206.0 | 105.2 |

| 48 | 47.5 | 1536 | 1140 | 226.0 | 117.2 |

| 50 | 50 | 1556 | 1160 | 250.1 | 124.3 |

Rigging Screw JIS F3403 Turnbuckle

If you choose a rigging screw with thimble, please contact us.

HangZhou Xinquanxi Metal Products Co., Ltd. was established in 2001 (formerly known as HangZhou Quanxi Rigging Hardware Co., LTD.), located in Wangyanzhuang North Village, Lancun Town, Xihu (West Lake) Dis. District, HangZhou city. In the early stage of establishment, the company mainly engaged in the production and sales of JIS turnbuckles and forging shackle, and successfully entered the Japanese market with high quality products and established the foreign trade Department. With the continuous development of the company’s business, in September 2019, it merged with HangZhou Ruihongjie Industry and Trade Co., LTD., and changed the company name to HangZhou Xinquanxi Metal Products Co., LTD. At the same time, the business scope has gradually expanded, the main production and operation of rigging, wire rope connection parts, precision machining, Pole line hardware, Marine and automotive connection parts, all kinds of forging, sheet metal, stamping, casting and other products.

Main products:

Rigging: turnbuckle (Jis open body, 1480 forging turnbuckle, US type forging turnbuckle,Rigging Screw), forging shackle, eye bolt and eye nut, forged hook, various sets of rings, D ring, master ring, snap hook,Pulley Block, etc.;

Corner code, expansion bolt, seismic support, guardrail and other building materials.

Casting pipes, manhole covers, road piles, container buttons, anchors, all kinds of breeding equipment and other casting products.

FAQ

1.Are you a factory or a trading company?

We have our own foundry and forging factory. The forging plant has 4 production lines and a history of more than 20 years;Foundry has a history of more than 30 years.

2.How do you control your quality?

1: Control during r&d at the beginning of production

2:Production process control

3:Dimensional control

4:Tensile tests

5:Quality inspection before delivery

3.Can we have our product markings on it?

Yes, we can add product markings according to your requirements.

4.How about packing?

Woven bag,carton,plywood pallet or by customer requirements.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | 25#,Q235 |

|---|---|

| Type: | Jaw & Jaw Turnbuckle |

| Usage: | Industrial, Household |

| Samples: |

US$ 5.5/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

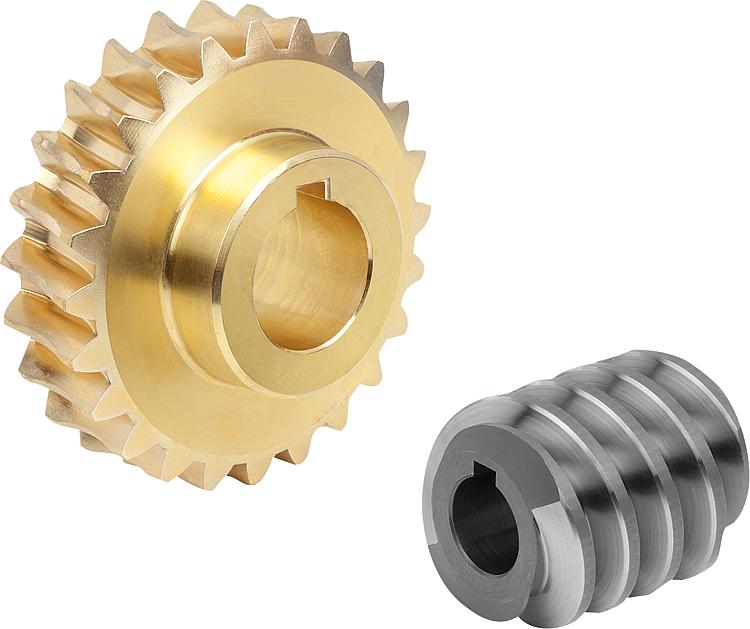

Can worm screws be used for high torque applications?

Yes, worm screws can be used for high torque applications. The design of a worm screw mechanism allows for efficient torque transmission and multiplication, making it suitable for applications that require high torque output. Here are some key points to consider regarding the use of worm screws in high torque applications:

- Gear Reduction: One of the primary advantages of a worm screw mechanism is its ability to provide a significant gear reduction in a single stage. The helical threads of the worm screw and the meshing teeth of the worm wheel create a high reduction ratio, which results in a lower output speed and higher output torque. This gear reduction capability allows worm screws to generate and transmit substantial torque, making them well-suited for high torque applications.

- Efficiency: While worm screws can provide high torque output, it’s important to consider the mechanical efficiency of the system. The efficiency of a worm screw mechanism can vary depending on factors such as the materials used, lubrication, and design parameters. However, compared to other gear systems, worm screw mechanisms tend to have lower efficiency due to inherent friction between the threads and teeth. It’s crucial to ensure that the efficiency of the worm screw mechanism meets the requirements of the specific high torque application.

- Load Holding: Another advantage of worm screws is their self-locking property. Due to the helical shape of the threads, the worm screw has a wedging effect on the worm wheel, which provides resistance against backward rotation. This self-locking feature allows worm screws to hold loads in a fixed position without the need for additional braking mechanisms. In high torque applications where load holding is required, worm screws can provide reliable and secure positioning.

- Material Selection: The materials used for the worm screw and worm wheel should be carefully selected to withstand high torque loads. Both components should have sufficient strength and wear resistance to handle the transmitted torque without deformation or premature failure. Depending on the specific application requirements, materials such as hardened steel, bronze, or other alloys may be chosen to ensure the durability and performance of the worm screw assembly.

- Lubrication and Maintenance: Proper lubrication is crucial for the smooth operation and longevity of a worm screw mechanism, especially in high torque applications. Adequate lubrication helps reduce friction, wear, and heat generation between the contacting surfaces, ensuring efficient torque transfer. Regular maintenance, including monitoring lubricant levels and replenishing or replacing the lubricant as needed, is essential to maintain optimal performance and prevent premature wear or failure.

Overall, worm screws can be effectively used in high torque applications, thanks to their gear reduction capabilities, load-holding properties, and efficient torque transmission. However, it’s important to carefully consider factors such as mechanical efficiency, material selection, lubrication, and maintenance to ensure that the worm screw mechanism can meet the specific requirements and demands of the high torque application.

Can worm screws be customized for specific engineering needs?

Yes, worm screws can be customized to meet specific engineering needs and application requirements. Customization allows for tailoring the design, dimensions, materials, and other parameters of the worm screw to optimize its performance and functionality. Here are some aspects of worm screws that can be customized:

- Thread Geometry: The thread geometry of a worm screw can be customized to suit specific requirements. This includes the shape, profile, lead angle, and thread form. Custom thread geometries can be designed to optimize load distribution, minimize friction, reduce backlash, improve efficiency, or achieve specific performance characteristics.

- Pitch and Lead: The pitch and lead of a worm screw can be tailored to meet the desired gear ratio, output speed, load capacity, and other performance criteria. Customizing the pitch and lead allows for precise control over the speed reduction or multiplication capabilities of the worm gear system.

- Materials: Worm screws can be customized to be made from different materials based on the specific application requirements. Common materials include steel, stainless steel, bronze, and various alloys. The choice of material depends on factors such as load capacity, durability, corrosion resistance, temperature tolerance, and other environmental considerations.

- Diameter and Length: The diameter and length of a worm screw can be customized to suit the mechanical constraints and dimensional requirements of the application. Custom sizing ensures proper fit, alignment, and integration within the overall system design.

- Coatings and Surface Treatments: Custom coatings or surface treatments can be applied to worm screws to enhance their performance and durability. These can include treatments such as hardening, heat treatment, plating, or specialized coatings to improve wear resistance, reduce friction, or provide corrosion protection.

- Special Features: Worm screws can be customized to incorporate special features or modifications based on specific engineering needs. This may include the addition of keyways, flanges, shaft extensions, or other components to facilitate integration with other system elements or to accommodate unique mechanical requirements.

Customization of worm screws requires collaboration between engineers, designers, and manufacturers with expertise in worm gear systems. It is important to define the specific engineering needs, performance requirements, and operational conditions to ensure that the customized worm screw meets the desired objectives effectively.

What are the advantages of using a worm screw in gear systems?

Using a worm screw in gear systems offers several advantages that make it a preferred choice in certain applications. Here are some of the advantages of using a worm screw:

- High Gear Reduction: One of the primary advantages of a worm screw is its ability to provide a high gear reduction ratio in a single stage. The helical threads of the worm screw and the meshing teeth of the worm wheel create a significant reduction in rotational speed. This allows for efficient torque multiplication, enabling the transmission of high torque output from the worm screw to the worm wheel. The high gear reduction is beneficial in applications that require slow and powerful movements, such as lifting heavy loads or controlling conveyor systems.

- Compact Design: Worm screw mechanisms are known for their compact design. Compared to other gear systems, such as spur gears or helical gears, a worm screw setup can achieve a similar gear reduction with fewer components. This makes it a space-saving solution, especially in applications where limited space is available or where a compact design is desired.

- Self-Locking: The self-locking property of a worm screw is a significant advantage in many applications. Due to the helical shape of the threads, the worm screw has a natural tendency to hold its position and prevent backward rotation of the worm wheel. This self-locking feature eliminates the need for additional braking mechanisms or external locking devices, simplifying the overall system design and improving safety and stability in applications that require load holding or position locking.

- Right-Angle Transmission: Worm screw mechanisms provide motion transmission at a right angle, allowing for the transfer of motion between non-parallel shafts. This makes them suitable for applications where the input and output shafts are oriented perpendicular to each other. Examples include automotive steering systems, where the rotational motion from the steering wheel needs to be converted into lateral motion for steering the vehicle.

- Quiet Operation: Worm screw gear systems tend to operate quietly compared to other gear configurations. The helical threads of the worm screw and the meshing teeth of the worm wheel engage gradually, resulting in smoother and quieter operation. This can be advantageous in applications where noise reduction is desirable, such as in office equipment, appliances, or environments where low noise levels are required.

It’s important to note that while worm screw mechanisms offer these advantages, there are also some considerations to keep in mind. For instance, worm screws can have lower mechanical efficiency compared to other gear systems due to inherent friction between the threads and teeth, leading to energy losses. Additionally, they may exhibit a certain amount of backlash, which can affect precision and introduce a small amount of lost motion in the system. Nevertheless, the unique characteristics of worm screws make them a valuable choice in various applications where high gear reduction, self-locking, compactness, and right-angle transmission are essential.

editor by Dream 2024-05-07