Product Description

Material: Stainless steel 303.

Special specifications products can be customized according to the customer request.

Hope you build up a long cooperation relationship with us; we will give you a discount and provide the free sample for your reference.

Looking CHINAMFG to your early inquiry.

| Products | Precision CNC machining parts | |

| Materials | Iron, aluminum, steel, copper, carbon steel, bronze, solder alloy, or as per the customers’ requirements. | |

| Dimensions | According to customer’ s drawing | |

| Surface treatment | Blacking, polishing, anodize, chrome plating, zinc plating, nickel plating, tinting or other as requirement. | |

| Packing | Bubble Bag, plastic bag, carton, plywood box, or as per the customer’ s requirements | |

| Standard | Such as ISO, DIN, GB, CHINAMFG and special standard | |

| Certificate | ISO9001: 2008 | |

| Processing equipment | CNC machine, CNC machining center, CNC cutting machine, radial drill, universal milling machine, high precision surface grinding machine, chamfering machine, etc. | |

| QC System | 100% during production check and random samples before shipment. | |

| Available | OEM, ODM | |

| MOQ | negotiable | |

| Ports | HangZhou or ZheJiang | |

| Delivery | Samples 7-15 days, batch production 30 days. |

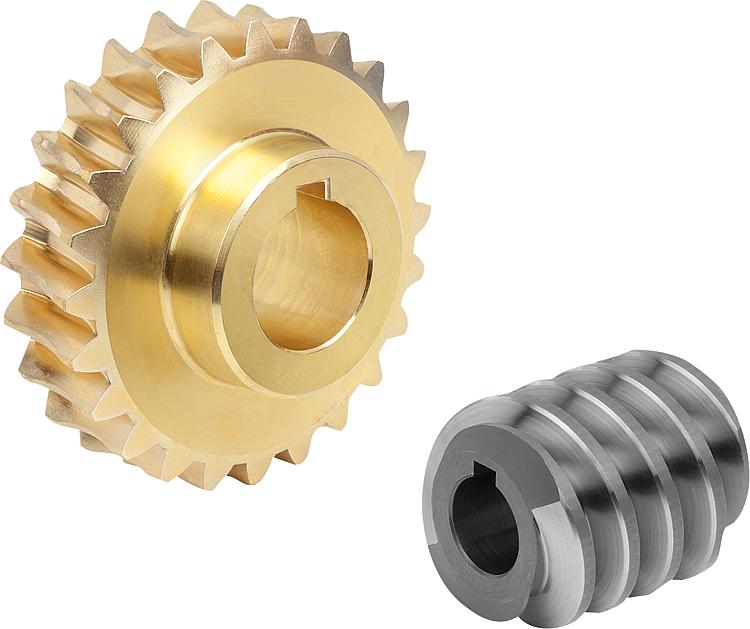

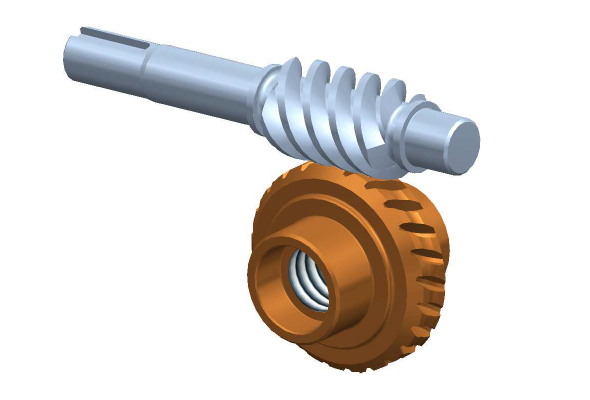

Nblangchi Transmission Technology is a professional manufacturer of lead screw, nuts, valve screw rod, worm and worm gear, which is used for transmission, lift, push-and-pull, fastening. We’re specialized in one-start lead screw, multi-start thread screw, left hand & right hand screw. Thread standard could be GB standard, German standard DIN103, American Standard ACME. The screw material could be carbon steel, alloy steel, stainless steel, copper, aluminum, etc.; nuts material could be brass, tin-bronze, Al-bronze, POM, carbon steel, cast iron, free-cutting steel, etc. Special specifications products can be customized according to the your request, including lead screws, nuts, M0.5-M6 modulus of the worm and the worm gear.

We have a full array of suitable equipment which is more than 250 sets, such as CNC lathe, machine center, milling machine, grinding machine, two-axis rolling and three-axis rolling, punching. Products are now more widely used in many areas. such as smart home, elderly chair, smart lifting table, smart door opener, smart window opener, smart lift, valve, farming machinery, sports equipment and so on. Our products are popular in domestic and foreign market. We mainly export goods to Europe, America and other international markets, which are well received by customers. Welcome come to visit our factory for business discussion, we will do our best to provide you with quality products and service. /* May 10, 2571 16:49:51 */!function(){function d(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What are the limitations of using worm screws in mechanical designs?

While worm screws offer several advantages in mechanical designs, they also have some limitations that should be considered. Here are the key limitations of using worm screws:

- Lower Mechanical Efficiency: Worm screw mechanisms tend to have lower mechanical efficiency compared to other gear systems. This is primarily due to the sliding contact between the worm screw threads and the worm wheel teeth, which results in higher friction and energy losses. The lower mechanical efficiency can lead to heat generation, reduced power transmission, and decreased overall system efficiency. It’s important to consider the trade-off between the desired gear reduction and the mechanical efficiency requirements of the specific application.

- Limited High-Speed Applications: Worm screws are not well-suited for high-speed applications. The sliding contact and meshing action between the threads and teeth can generate heat and cause wear at high rotational speeds. Additionally, the higher friction and lower mechanical efficiency mentioned earlier can limit the maximum achievable speed of the system. If high-speed operation is a requirement, alternative gear systems, such as spur gears or helical gears, may be more suitable.

- Backlash: Worm screw mechanisms can exhibit a certain amount of backlash, which is the lost motion or clearance between the threads and teeth when changing direction. Backlash can negatively impact precision and positioning accuracy in applications that require tight tolerances. It’s important to consider backlash and implement measures to minimize its effects, such as using anti-backlash mechanisms or incorporating backlash compensation techniques.

- Material Selection: The choice of materials for worm screws is crucial to ensure their durability and performance. Worm screws typically require harder materials to withstand the sliding contact and high contact pressures between the threads and teeth. The selection of suitable materials may increase the manufacturing complexity and cost of the worm screw assembly. Additionally, the choice of materials should consider factors such as compatibility, wear resistance, and the specific operating conditions of the application.

- Load Distribution: In worm screw mechanisms, the load is distributed over a limited number of teeth on the worm wheel. This concentrated load distribution can result in higher stresses and wear on the contacting surfaces. It’s important to consider the load capacity and contact area of the worm wheel teeth to ensure that the assembly can handle the anticipated loads without premature failure or excessive wear.

- Required Lubrication: Proper lubrication is crucial for the smooth operation and longevity of worm screw mechanisms. Lubrication helps reduce friction, wear, and heat generation between the contacting surfaces. However, the need for lubrication adds complexity to the design and maintenance of the system. It requires regular monitoring of lubricant levels and periodic lubricant replenishment or replacement. Failure to maintain proper lubrication can result in increased friction, wear, and potential system failure.

Despite these limitations, worm screws continue to be widely used in various mechanical designs due to their unique characteristics and advantages. It’s essential to carefully evaluate the specific requirements and constraints of the application and consider alternative gear systems if the limitations of worm screws pose significant challenges to the desired performance and efficiency.

What are the latest innovations in worm screw design and materials?

In recent years, there have been several notable innovations in worm screw design and materials that aim to improve performance, efficiency, durability, and overall functionality. Here are some of the latest advancements in this field:

- Advanced Materials: One of the significant trends in worm screw design is the use of advanced materials. Manufacturers are exploring materials with enhanced strength, wear resistance, and fatigue properties. For example, advanced alloys and composite materials are being employed to improve load capacity, reduce weight, and increase the longevity of worm screws. Additionally, advancements in material science and engineering are leading to the development of self-lubricating materials, which can minimize friction and improve efficiency by reducing the need for external lubrication.

- Improved Thread Geometries: Innovations in thread geometries have focused on optimizing load distribution, reducing friction, and improving efficiency. Researchers and engineers are developing novel thread profiles and forms that enhance contact between the worm screw and the worm wheel. These designs help minimize backlash, increase load-carrying capacity, and improve overall system performance. Additionally, advancements in computer simulations and modeling techniques enable more accurate analysis and optimization of thread geometries for specific applications.

- Surface Treatments and Coatings: Surface treatments and coatings are being applied to worm screws to enhance their performance and durability. For instance, advanced coatings such as diamond-like carbon (DLC) coatings or specialized lubricious coatings help reduce friction, improve wear resistance, and minimize the need for external lubrication. Surface treatments like nitriding or carburizing can improve hardness and provide resistance against abrasive wear, increasing the lifespan of worm screws.

- Precision Manufacturing: Innovations in manufacturing processes and technologies have enabled the production of worm screws with higher precision and tighter tolerances. Advanced machining techniques, such as CNC grinding and high-precision gear hobbing, allow for the creation of worm screws with superior dimensional accuracy, improved surface finish, and better tooth profile control. These manufacturing advancements contribute to enhanced performance, reduced backlash, and increased overall system efficiency.

- Computer-Aided Design and Simulation: The use of computer-aided design (CAD) software and simulation tools has revolutionized worm screw design and optimization. Engineers can now create virtual models, simulate the behavior of worm gear systems, and analyze various design parameters to optimize performance before physical prototypes are manufactured. This iterative design process helps reduce development time, minimize costs, and improve the final design and performance of worm screws.

- Integration with Digitalization and Automation: The integration of worm gear systems with digitalization and automation technologies is another area of innovation. Worm screws are being designed to work seamlessly with sensor technologies, allowing for real-time monitoring of performance parameters such as temperature, vibration, and load. This data can be utilized for predictive maintenance, condition monitoring, and optimization of the overall system performance.

It’s important to note that the field of worm screw design and materials is continuously evolving, and new innovations are being introduced regularly. Keeping up with the latest research, advancements, and industry developments is crucial for engineers, designers, and manufacturers involved in worm gear system applications.

How do you calculate the gear ratio for a worm screw and gear setup?

In a worm screw and gear setup, the gear ratio is determined by the number of teeth on the worm wheel (gear) and the number of threads on the worm screw. The gear ratio represents the relationship between the rotational speed of the worm screw and the resulting rotational speed of the worm wheel. The formula to calculate the gear ratio is as follows:

Gear Ratio = Number of Teeth on Worm Wheel / Number of Threads on Worm Screw

Here’s a step-by-step process to calculate the gear ratio:

- Count the number of teeth on the worm wheel. This can be done by visually inspecting the gear or referring to its specifications.

- Count the number of threads on the worm screw. The threads refer to the number of complete turns or helical grooves wrapped around the cylindrical body of the worm screw.

- Divide the number of teeth on the worm wheel by the number of threads on the worm screw.

- The result of the division is the gear ratio. It represents the number of revolutions of the worm screw required to complete one revolution of the worm wheel.

For example, let’s say the worm wheel has 40 teeth, and the worm screw has 2 threads. Using the formula, we can calculate the gear ratio as follows:

Gear Ratio = 40 teeth / 2 threads = 20

In this case, for every full revolution of the worm screw, the worm wheel will rotate 1/20th of a revolution. This indicates a significant speed reduction, resulting in high torque output at the worm wheel.

It’s important to note that the gear ratio calculated using this formula assumes an ideal scenario without considering factors like friction, efficiency losses, or the pitch diameter of the gears. In practical applications, these factors may affect the actual gear ratio and performance of the worm screw and gear setup.

<img src="https://img.hzpt.com/img/screwshaft/Honeyview_screwshaft-l1.webp" alt="China factory Trapezoidal Stainless Steel Thread Lead Screw for Machinery Tr20X4 “><img src="https://img.hzpt.com/img/screwshaft/Honeyview_screwshaft-l2.webp" alt="China factory Trapezoidal Stainless Steel Thread Lead Screw for Machinery Tr20X4 “>

editor by Dream 2024-10-18